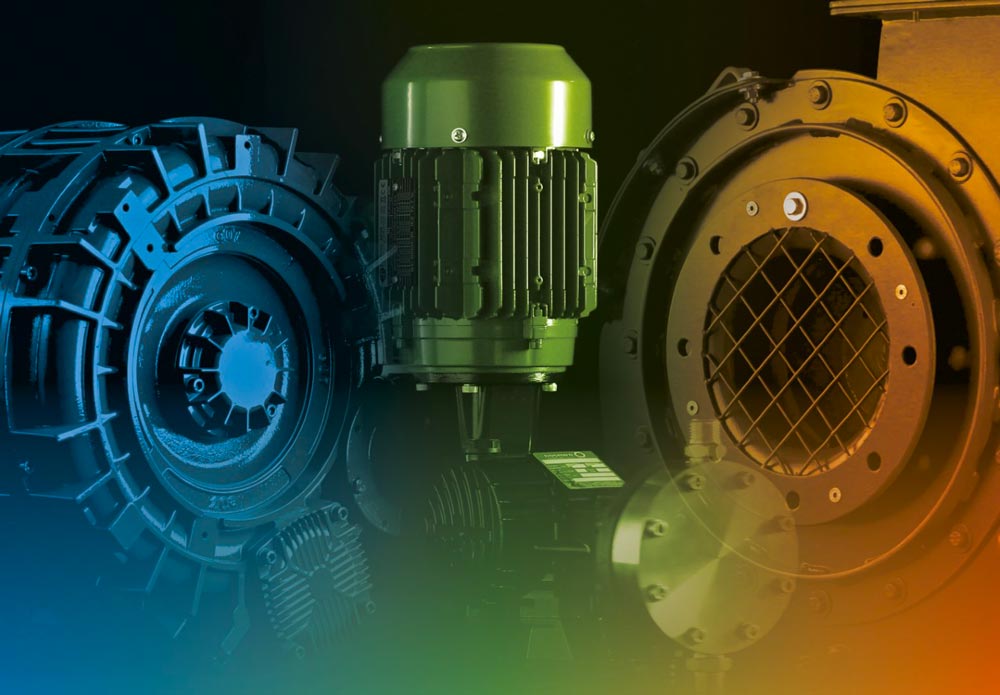

FPZ Extreme Conditions Blowers

Designed to operate reliably in high-temperature or corrosive environments

Our range of blowers

ALUMINIUM STANDARD BLOWERS

Designed for clean air for fluids (air and technical gases) with a maximum temperature of 120°C.

Available in: e Series, K Series, R Series.

HT SERIES BLOWERS

Engineered for high-temperature processes and hot-gas recirculation.

Includes special models: HT MOR 200°C (aluminium) and HT GOR 350°C (stainless steel).

STAINLESS STEEL BLOWERS 316L

Built for corrosive environments and demanding industrial conditions.

Made entirely of 316L stainless steel for maximum durability.

Benefits: why choose FPZ blowers

FOR A SINGLE SUPPLIER COMPLETE PACKAGE

FLEXIBILITY

EASY MAINTENANCE

Repair kit available

FPZ Aluminium Special Blowers

FPZ high-temperature blowers are engineered for reliable operation in demanding environments, tolerating discharge temperatures up to 200 °C.

Featuring an aluminum base and stainless steel components, they ensure extended service life under severe thermal stress.

Crucially, they maintain the same low noise levels as our standard models while guaranteeing excellent durability and performance consistency.

FPZ Stainless Steel Blowers

FPZ stainless steel blowers are specifically engineered to perform with corrosive fluids in the most and handle even the toughest industrial applications with confidence.

Built with top quality materials and reinforced through a solid, precision construction, they are designed to resist wear, protect against damage, and deliver consistent results.

This combination of strength and durability ensures not only outstanding reliability, but also long-lasting performance that operators can count on day after day.

Stainless Steel special blower for fuel cell

The new HT Series blower from FPZ is a game-changer in the industry. Thanks to its special configuration and magnetic coupling, it is designed to handle air and technical gases of various compositions at high temperatures up to 350°C.

Fuel cells: green energy for the future

Fuel Cells (FC) are innovative systems for clean energy generation. They use hydrogen and natural gases to produce electricity with high efficiency and low emissions.

How do SOFCs work

1

Air is introduced into the cell through a standard side channel blower.

2

The fuel (Hydrogen, Natural Gas, Methane, Liquefied Natural Gas, Phosphoric Acid) reacts inside the cell at high temperatures (750–800°C), generating energy.

3

The residual gas from the reaction, which can reach up to 300°C, is managed by the new high-temperature blower, designed to withstand extreme conditions.

About FPZ

Thanks to 50-plus years of experience in the design and production of fluid handling technologies, today FPZ products are the industry standard in over 200 different applications with thousands of machines installed over 5 continents.

FPZ, with its 10 branches (UK, Spain, France, Germany/Austria, Turkey, USA, Mexico, Middle East, China, Korea) is able to guarantee pre- and post-sales assistance worldwide.

Discover the benefits that our Extreme Conditions Blowers can bring to your company

Fill out the form to be contacted by one of our specialists free of charge and discuss the FPZ solution that best fits your needs.